Gen-Hy

offers you its Gen-AEM CCMs (catalyst coated membranes).

Designed

and produced by Gen-Hy Cube, our ceramic-based CCMs is free of any rare earth materials. Gen-Hy Cube is the only European company that offers this!

Sold by linear meter to suit your needs, Gen-AEM membranes fit all electrolyte-based stacks.

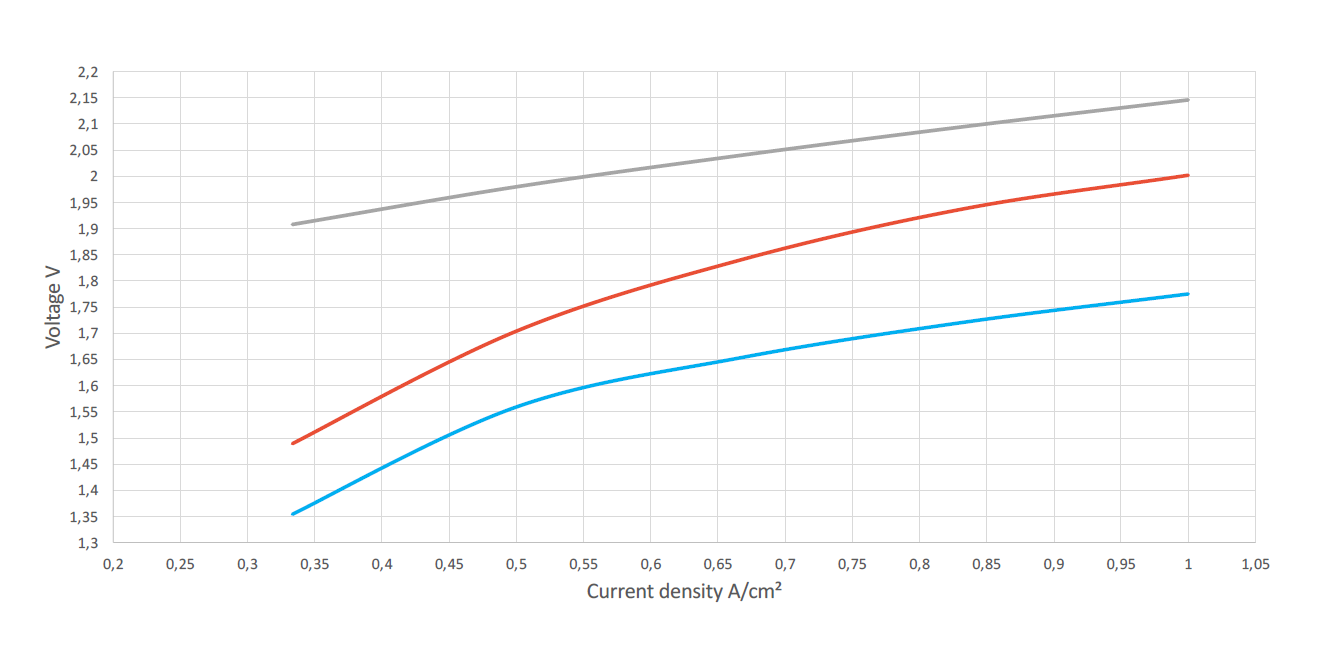

GEN-AEM catalyst coated membrane without PGM

GEN-AEM membrane without catalyser

Concurrency membrane without catalyser

Pem Technology

Alkaline Technology

There are several methods for producing hydrogen. In order to meet the decarbonization targets set out in the French government's "2030 Plan", the challenge was to find a low-carbon, energy-efficient solution with the lowest costs. GEN-HY Cube chose the solution of water electrolysis, which consists of separating water molecules to obtain hydrogen and oxygen using electrical energy.

In an electrolyser unit, two distinct chambers are separated by a separator or a membrane, the hydrogen and oxygen produced by the electrodes. This separation allows to avoid the gas mixture and allows ions to circulate. In a conventional alkaline electrolysis, a separating diaphragm is placed between the two chambers as separator. The diaphragm allows the liquid to pass through microholes while also forming a barrier that keeps out and separates mostly the gas produced in both chambers. However, conventional solutions are imperfect. Gas mixing, also known as ‘cross-over’, reduces the yields and purity of the gases produced, and is therefore undesirable. Larger gaps between electrodes increase the voltage required for electrolysis, also reducing yield. To solve this, the GEN-AEM® membrane developed by GEN-HY CUBE allows ions to pass through while remaining gas-tight.

GEN-HY CUBE has designed its stacks (hydrogen generators) around its CCM GEN- AEM® in a zero-gap architecture. By placing the electrodes in contact with the CCM, GEN-HY CUBE achieves high efficiencies of 85% (High Heating Value), with high productions hydrogen purity.

| GEN-AEM® with catalysts coating | Units | GEN-AEM |

| Membrane Type | NA | AEM Mixed Matrix Membrane |

| Appearance / shape | NA | White / Souple |

| Thickness | μm | 500 ± 5% |

| Weight | g/m² | 1600 ± 5% |

| Maximum operating temperature | °C | 100 |

| Range of operating pH | PH | 0 to 14 |

| Ionic conductivity at 25°C in 1 molar KOH | mS/cm | 100 |

| Hydrogen cross over | mol.cm-1.Pa-1.s-1 | 1.00E-12 ± 10% |

| Young Modulus for non reinforced membrane at 25°C | MPa | >120 |

| Tensile strength at 25°C | MPa | >0,1 |

| Elongation at break at 25°C | % | >14 |

| Young Modulus for reinforced membrane at 25°C | MPa | >2000 |

| Tensile strength at 25°C | MPa | >200 |

| Elongation at break at 25°C | % | >30 |

| PGM* free catalyser for cathode side (optional) | mg/cm² | 4 |

| PGM* free catalyser for anode side (optional) | mg/cm² | 4 |