Durability and lifetime testing under various operating conditions

ELECTROLYSER TEST BENCH

FOR HYDROGEN SOLUTIONS

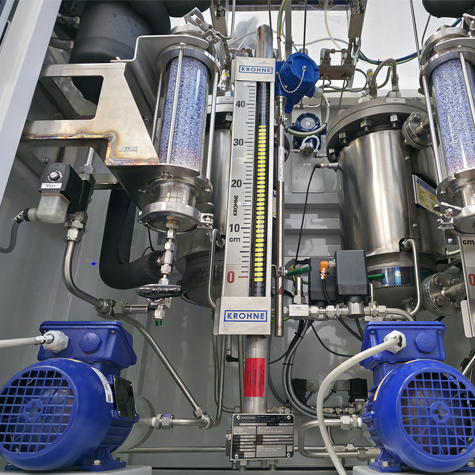

GEN-HY has developed an industrial electrolyser test bench designed for all stakeholders in the hydrogen value chain who need to qualify their processes and their green hydrogen production by electrolysis

GEN-HY’s industrial electrolyser test bench supports stakeholders throughout the hydrogen value chain, enabling them to qualify their processes and thier green hydrogen production through electrolysis

H2TEST RANGE

AEM / Alkaline / PEM Stacks

Stacks testing, characterization and polarization curves

Hydrogen gas flow rate measurements and LEL monitoring (Lower Explosive Limit)

Voltage measurements and efficiency calculation

Automatic operation using a PLC unit to control, configure and monitor the system operating parameters

APPLICATIONS

The versatility of GEN-HY's test bench enables a wide range of specific tests throughout the green hydrogen production process:

Electrolyser technology optimization

Direct support for R&D teams

Prototype evaluation

For mobility, ESS and industrial applications

Research and development

In the mobility, transport and energy industry sectors

Validation of performance

Electrical, mechanical and fluidic performance validation

Endurance and reliability testing

Under simulated real life operating conditions

Lifetime, safety and security analysis

Risk prevention, regulatory compliance and system reliability assurance

Resistance and stress testing

Verification of material durability under real constraints

Stack efficiency

Simulation of characterization and polarization curves for efficiency measurements

GENERAL TECHNICAL

SYSTEM SPECIFICATIONS

- Produced gases analysis (hydrogen and oxygen)

- Production with controlled electrical power supply with a maximum capacity of 3 kW (depending on the required power level)

- Balanced operating pressure control between hydrogen and oxygen circuits

- Production pressure up to 5 bar

- Electrolyte heating system from 40°C to 85°C

- Control of operating conditions (pressure, temperature, electrolyte type, flow rate and power supply)

- Automatic addition of purified water at operating pressure

- Safe evacuation of produced gases (hydrogen and oxygen)

- Lifespan tests of stacks up to 3 kW of power

- Recording of operating data and events

- Mobile system

- Integrated HMI interface with touch screen control

- Autonomous operation

- Safe and secure system

- Stack capacity up to 10 cells

- Integrated gas analysis units

The test bench operates fully automatically via a PLC unit that controls and monitors the entire system operating parameters

Programmable Logic Controller

(PLC)

The test bench is equipped with flexible control software, a user friendly interface, and advanced automation capabilities

Thanks to its intuitive touch screen, the operator can:

- Perform maintenance operations

- Configure and control the system

- Select operating modes

- Display operating curves

- Monitor system performance

- View alarms and alerts

Options:

- Water supply level monitoring and control

- Electrolyte flow rate measurement

- Custom stack study

Technical specifications

| Stacks | Power | 1 stack 3 kW |

| Type | AEM / PEM / ALKALINE | |

| Power | Rectifier | DC 80V / 37,5A pilotable |

| Operating Conditions |

Operating pressure range | from 1 to 5 bars |

| Operating temperature | Ambient temperature (-85°C) | |

| System's fluids |

Electrolyte for alkaline and AEM stacks | Basic (KOH or NaOH 6M max) |

| Electrolyte for PEM stacks | Pure water | |

| Electrolyte separation tanks | 17L | |

| Réservoir de stockage d’eau | 50L | |

| Storage tank of new electrolyte | 20L | |

| Gas analysis |

Production rate | l/min |

| LIE | % | |

| Dimensions | Width | 250 cm |

| Height | 220 cm | |

| Depth | 150 cm | |

| Weight | 750 kg (unladen) |

ADVANTAGES

| Ease of use | Guided and intuitive touch interface – automated processes. |

| Safety | CE certified – automated process with alarm management. |

| Reliability |

CE certification by approved bodies. Equipment validated over 8,000 operating hours. Use of components compliant with current regulations. |

| Versatility |

Wide test range for complete validation. Endurance and performance testing. Electrical power range between 100 W and 3 kW. Capacity up to 10 cells. Compatibility with all electrolysis technologies (AEM, PEM, Alkaline). |

| Purchase / Rental |

Purchase: competitive pricing with customization options. Long term rental available in France for stakeholders seeking flexible investment solutions. Possibility of maintenance contract and technical training. |

| Reliability |

CE certification by approved bodies. Proven equipment with over 8,000 operating hours. Use of regulation compliant components. |

| Adaptability | Customizable test protocols based on load profiles. |

| Autonomy | Autonomous operation – automated processes. |

| Safety | CE certified – automated process with alarms. |

| Ease of use | Guided and intuitive touch interface. |

| Versatility |

Comprehensive test range. Endurance and performance testing. Electrical power from 100 W to 3 kW. Stack up to 10 cells. Compatible with AEM, PEM and alkaline electrolysis technologies. |

| Traceability | Recording of operating data and events. |

| Full integration | Complete technical support including installation and training. |

| Long term support | On site installation, maintenance and technical training. |

| Purchase / Rental |

Purchase: competitive pricing with customization options. Long term rental available in France for reduced capital investment. |

Commissioning

& Training

At your facility

GEN-HY provides full project support, including:

- On site installation of the test bench

- Comprehensive team training

- Maintenance contract

- Detailed explanation of all functionalities

Our goal: to ensure optimal and autonomous operation from day one.

Ready to accelerate your hydrogen test program?

Your contact

PhD in Process Engineering, Mechanical engineer

ABOUT GEN-HY

GEN-HY specializes in the design of innovative energy solutions with a strong commitment to carbon neutrality.

The company offers a complete hydrogen value chain, including electrolyser test benches.

Leveraging its expertise in design, manufacturing and advanced technologies, GEN-HY delivers customized solutions tailored to the diverse needs of its clients.

In addition, GEN-HY designs and manufactures proprietary hydrogen electrolysers aimed at optimizing hydrogen production for clean mobility, storage and energy supply applications.

These solutions are designed to harness renewable energy and support a sustainable, efficient and environmentally responsible energy transition.